I spent the summer of 2024 interning with Bastian Solutions - A Toyota Automated Logistics Company as a Mechanical Design Engineer Intern. In this role, I took on a number of different projects, from design to programming to automation.

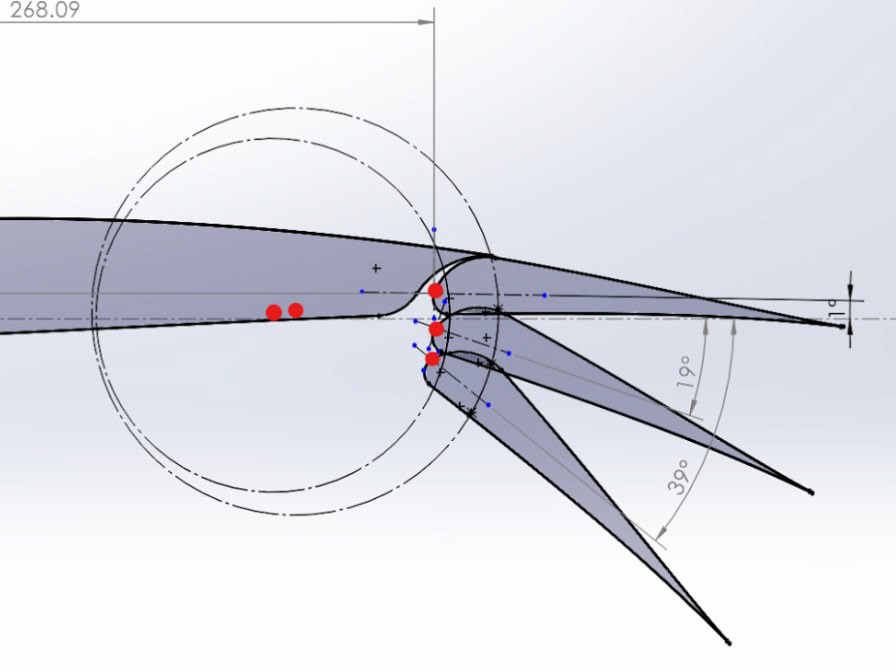

My internship work focused primarily on design updates to the ULTRA Loader/Unloader robots. I performed materials analysis on the machine's guiderails, leading to a successful redesign. Through this process, I learned about repetitive bending fatigue and reviewed the latest literature on the subject. I then oversaw the manufacturing and assembly of my redesigned system.

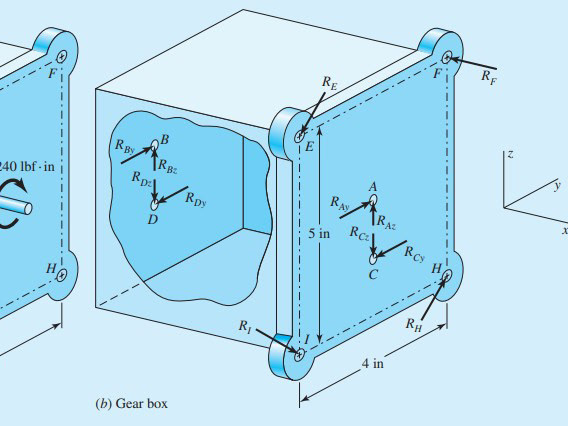

Early on in my internship, I noticed some kinematic design flaws in the robot's end-of-arm-tooling gearbox mounting system. This led to me redesigning the mount, forcing me to combine knowledge of robot kinematics and control with computer-aided design and materials selection.

I was also tasked with integrating a bearing system to an overconstrained linkage, which lead to an iterative process which saw me presenting various designs to the wider team. After deciding on a solution, I created all the relevant engineering drawings, drawing on knowledge of GD+T, DFM, and DFA, resulting in a successful system integration.

I also developed an interactive python-based app which computed and visualized box-packing solutions. The 3D-graphics that my program outputs have already been used in meetings with potential clients, to show them what Bastian's robots are capable of!

Aside from these projects, I also personally designed numerous mounts for electrical components such as LIDAR sensors and limit switches. The fast-paced, ever-improving nature of R+D engineering created an environment in which I thrived, and I developed my ability to think on my feet and solve problems creatively and quickly.

While I can't share photos of active R+D projects publicly, enjoy this picture of me with one of the ULTRA robots!