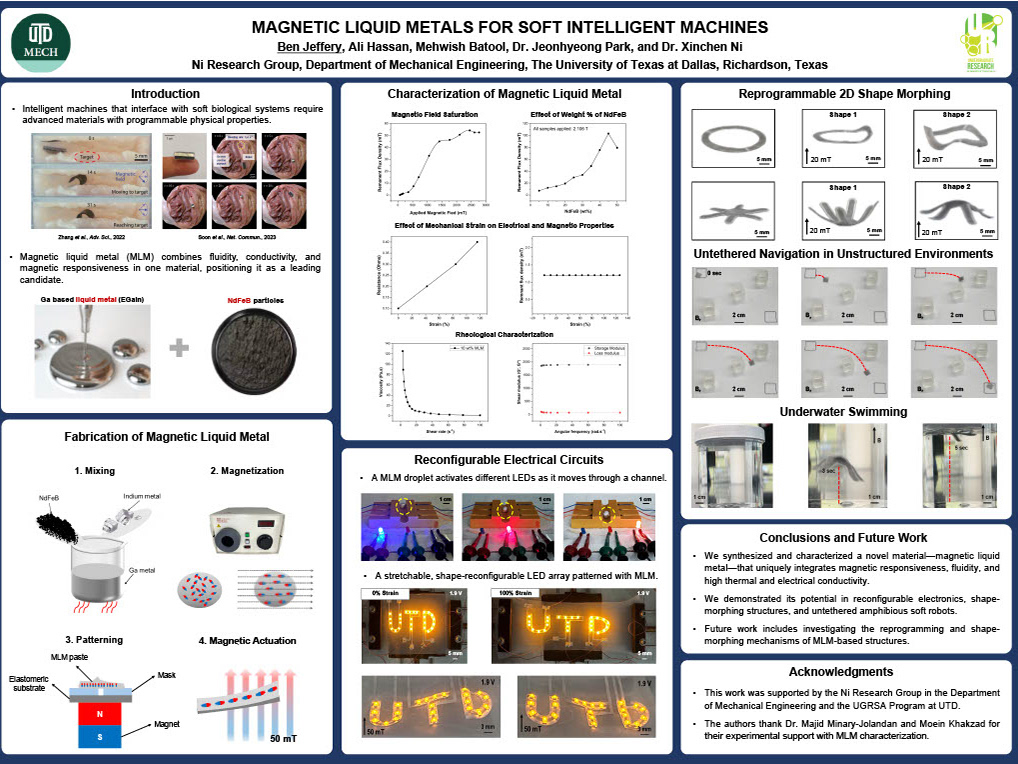

During the 2023-2024 academic year, I was the mechanics team lead for UT Dallas's competitive Design/Build/Fly competition team. During the year, I led a team of ~15 engineering students through iterative design, manufacturing, and testing of remote-controlled aircraft structure, landing gear, and payloads.

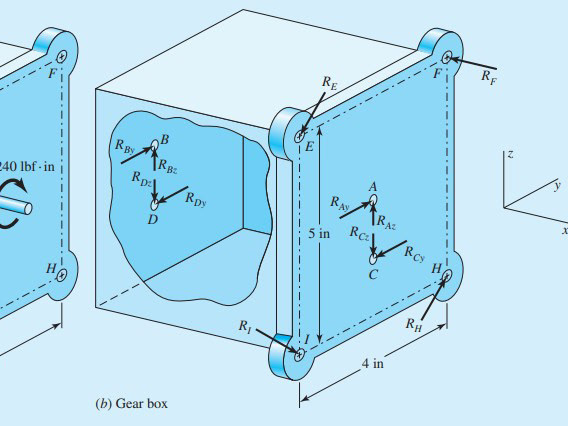

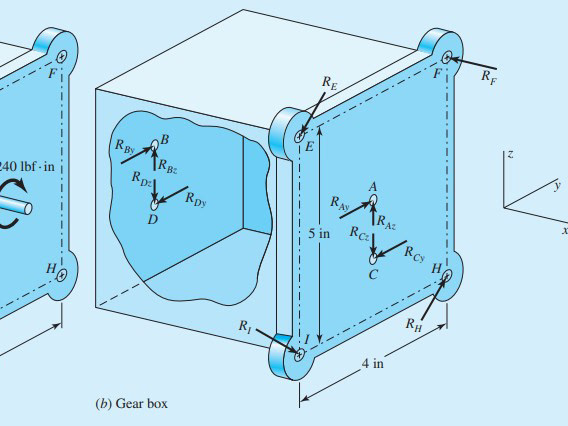

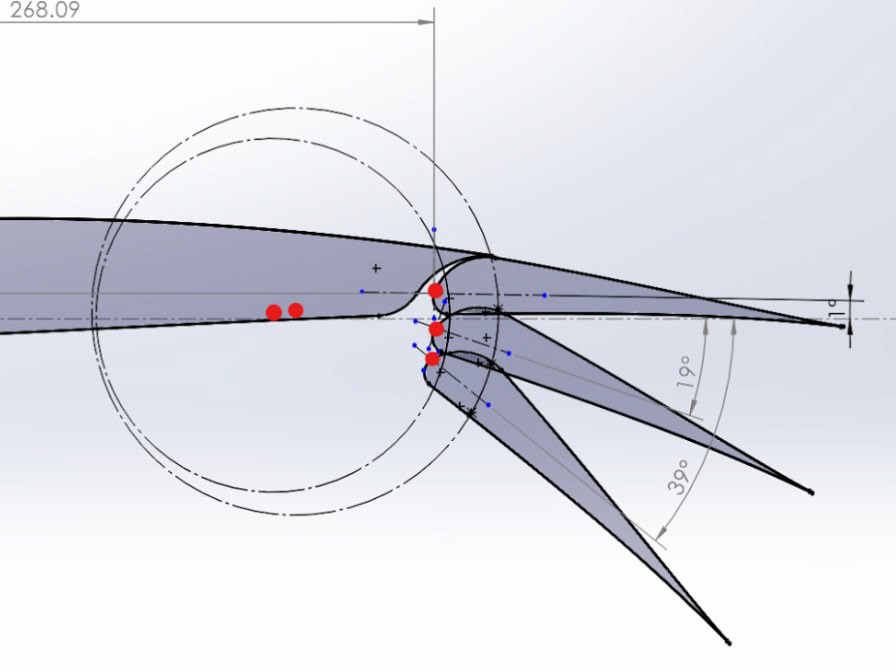

As mechanics team lead, I was responsible for the design and fabrication of our aircraft's fuselage, including ensuring the swift insertion and removal of heavy payloads (something teams were scored on). It was my responsibility to ensure that our plane (which was made predominantly of lightweight balsa wood) would be able to withstand the various forces exerted on it (g-forces, payloads, landing loads, etc). It was also my job to ensure smooth system integration, so I worked closely with project management and the other technical leads (aerodynamics and electronics) to achieve this.

During this project, I gained experience with SOLIDWORKS, materials selection and stress analysis, incorporating DFM and DFA knowledge into the design, before collaborating with the whole team to manufacture three aircraft. I also led new members of the team through laser cutter training sessions, working carefully to ensure that all members of the group felt included and valued for the duration of the project.

I also managed the team through the planning and writing process of our sixty-page technical report, which placed 1st out of six teams across Texas! Most importantly, our team placed 1st in the world among schools without an aerospace program!

Check out this cool drone footage that we took at one of our test flights in Princeton, TX. The flight starts at around the 2:35 mark in the video!

Also, check out our technical design report (which, as mentioned above, placed 1st in Texas) here!